Demystifying How a Commercial HVAC System Works

September 12, 2023

Your Guide to Hiring the Perfect HVAC Contractor

November 11, 2023Ever been in a factory or warehouse, feeling the comfort of cool air on a hot summer’s day? That’s no miracle. It’s thanks to industrial HVAC systems.

You might ask, “What exactly is an industrial HVAC?” Let me tell you – it’s more than just cooling large spaces. Industrial Heating, Ventilation, and Air Conditioning (HVAC) systems are complex beasts that regulate temperature and air quality across huge areas. They’re crucial for many industries to function correctly.

In this exploration, we’ll delve into the nuts and bolts of these machines – from their components to their types, maintenance needs, and even future trends. We’ll also tackle why they matter so much for various businesses.

Ready to uncover the mysteries of industrial HVAC systems? Hang tight because this ride will be nothing short of enlightening!

Table Of Contents:

- Understanding Industrial HVAC Systems

- Importance of Industrial HVAC Systems

- Types of Industrial HVAC Systems

- Energy Efficiency in Industrial HVAC Systems

- Maintenance and Servicing of Industrial HVAC Systems

- Cost Factors in Industrial HVAC Systems

- Future Trends in Industrial HVAC Technology

- FAQs in Relation to Industrial HVAC

- Conclusion

Understanding Industrial HVAC Systems

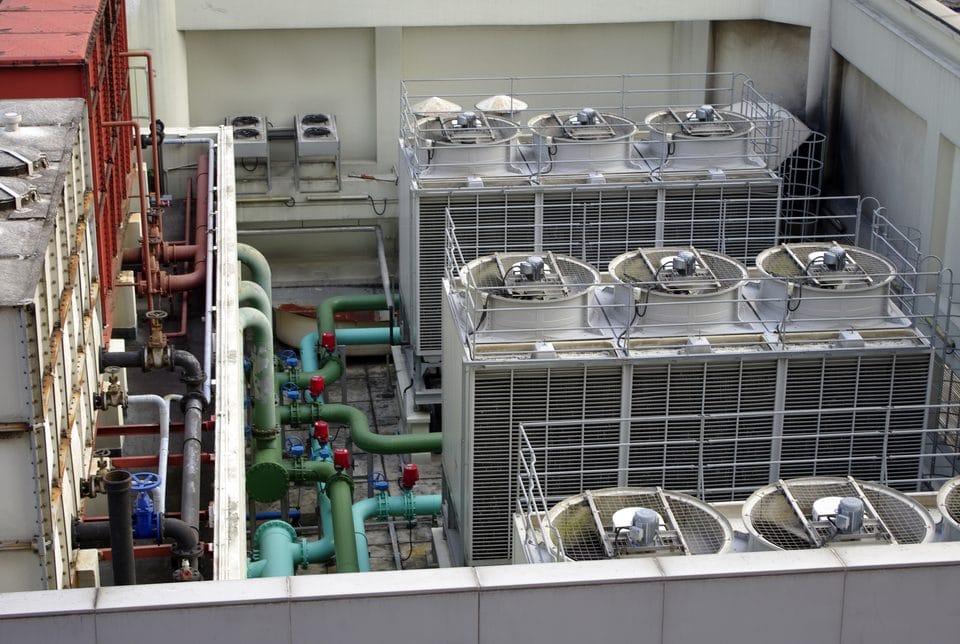

Industrial Heating, Ventilation, and Air Conditioning (HVAC) systems are more than just giant versions of your home units. They’re complex machines that manage climate control for large spaces like factories or office buildings.

The central air conditioner of an industrial HVAC system is responsible for cooling the air using a refrigeration cycle. But that’s not all there is to it.

Main Components of Industrial HVAC Systems

An industrial HVAC system typically includes three main components: an evaporator coil, a compressor, and a condenser coil.

- The evaporator coil absorbs heat from indoor air using refrigerant – like how your skin feels cool when water evaporates.

- This warmed-up refrigerant then travels to the compressor, which pressurizes it into hot gas – similar to inflating a bike tire with so much force that it heats up.

- Last but not least comes the condenser coil, where this heated gas releases its captured heat outside, turning back into liquid form, ready for another round in the cooling relay race.

Differences Between Residential and Industrial Units

So, what makes these beasts different from their residential counterparts? Size matters, yet there’s more than what appears.

Beyond sheer capacity differences between commercial-grade equipment used by companies like us at Calmech versus smaller household systems, controls play a significant role, too. For instance, humidity controls are more common in industrial systems to help maintain specific humidity levels for particular processes or comfort.

Another critical difference is redundancy. If your HVAC system fails in a residential setting, it’s inconvenient but not catastrophic. But imagine an industrial plant losing its climate control – production could halt. So, most commercial units have built-in redundancies to ensure they keep running no matter what.

Industrial HVAC systems aren’t just bigger versions of home units – they’re complex machines designed for big spaces like factories. With main parts, including an evaporator coil, a compressor, and a condenser coil, these beasts use the refrigeration cycle to cool air. Unlike residential units, industrial ones often have built-in redundancies and humidity controls for specific needs.

Importance of Industrial HVAC Systems

Even if we’re unaware, industrial HVAC systems play a pivotal role in our daily lives. These robust machines are the silent guardians that ensure optimal working conditions in factories, warehouses, and other industrial settings.

An HVAC system, or Heating, Ventilation, and Air Conditioning system, regulates the indoor environment in industrial settings. But when you scale this up to an industrial level, there’s more at stake than comfort.

Air Quality Control

In any workspace, clean air is crucial for employee health and safety. This becomes especially important in manufacturing industries where dust particles can be prevalent. Here’s where your trusted HVAC comes into action: filtering out harmful pollutants from the air before they reach human lungs.

Besides safeguarding workers’ health, maintaining good indoor air quality protects machinery from premature wear and tear caused by airborne debris accumulation.

Temperature Regulation

Temperature control goes beyond keeping staff comfortable – it can also be vital for specific business operations. Think about food processing plants or pharmaceutical companies; these businesses need specific temperature ranges to preserve product integrity.

Ice cream won’t stay frozen long on a hot summer day without proper cooling if temperatures soar too high or plummet too low due to equipment malfunctions or weather changes.

Economic Efficiency

Last but certainly not least: cost savings. A well-maintained industrial HVAC unit operates efficiently with less energy wastage, which means lower utility bills for businesses. Additionally, Energy Star estimates that a well-functioning HVAC system can save up to 10% on annual energy costs.

In summary, the importance of industrial HVAC systems extends far beyond comfort. They ensure healthy working conditions, aid in maintaining product quality, and contribute to economic efficiency – proving they are indeed an essential piece of equipment in any industry.

Industrial HVAC systems are unsung heroes, keeping workspaces safe and efficient. They’re vital for air quality control, protecting worker health and machinery longevity. Temperature regulation isn’t just about comfort; it’s key in preserving product integrity in businesses like food processing or pharma. Plus, a well-maintained unit saves money by cutting energy costs.

Types of Industrial HVAC Systems

Industrial HVAC systems are a world apart from their residential counterparts. Their sheer size, complexity, and the specific demands they need to meet make them unique.

Single Split System

The single split system, an ideal choice for small businesses, offers excellent affordability. It’s perfect for controlling individual room temperatures. However, keep in mind that each unit needs its outdoor component.

Multisplit System

If you’ve got more space or want greater control over your environment without having numerous exterior units littering your premises, consider multisplit systems. These allow multiple interior units to connect with one external condenser.

VRF and VRV Systems

Larger commercial spaces might find Variable Refrigerant Flow (VRF) or Variable Refrigerant Volume (VRV) systems more suitable because of their efficiency and flexibility. Daikin, a leading manufacturer of these industrial HVAC systems, says it best: “Get optimal comfort with energy savings.”

Packaged Heating & Cooling Units

Last is the packaged heating & cooling unit option, which houses all components in one neat package. Due to their bulkiness, ASAP Heating And Cooling is often found on rooftops, which explains why this could be a great option for you.

No solution is ideal for all industrial HVAC requirements; each system has advantages and disadvantages. Each system has its pros and cons, depending on your specific needs. Always seek the advice of an experienced specialist before settling on a choice.

Making the Right Choice

How does one decide which option is the optimal choice? That depends mainly on your unique requirements – size of premises, energy efficiency goals, budget constraints, and more. A chat with experts like Calmech, who specializes in large commercial HVAC installation, can give valuable insights to help make that choice easier.

Industrial HVAC systems are tailored to specific needs, from single split systems for small businesses to multisplit and VRF/VRV options for larger spaces. When choosing a system, consider your unique requirements like size, energy efficiency goals, and budget. Remember: expert advice can make the choice easier.

Energy Efficiency in Industrial HVAC Systems

An industrial HVAC system is like the lungs of a building, circulating air and maintaining a comfortable environment. Maintaining energy efficiency is essential for more than just cutting costs.

The Importance of Energy Efficiency

Achieving high energy efficiency isn’t simply about reducing costs – though that’s an attractive perk. It also helps to reduce carbon emissions, making your operations more sustainable.

By implementing some basic energy-saving measures, commercial buildings can save up to 10% on their heating and cooling bills, according to the U.S. Department of Energy.

Ways To Improve Energy Efficiency

Making an industrial HVAC system more efficient might seem daunting, but there are several straightforward steps you can take:

- Scheduled maintenance: Regular checks ensure everything is running smoothly and efficiently. Preventive upkeep prevents minor issues from becoming big problems down the line.

- Upgrade old systems: Older equipment often consumes more power than newer models designed with modern standards in mind. An upgrade could mean substantial savings over time.

- Better insulation: Proper insulation reduces heat loss or gains from outside, meaning less work for your HVAC unit and reduced energy consumption overall.

The Benefits Of An Efficient System

Economically speaking, lower operating costs due to increased efficiency directly impact bottom lines – money saved here can be invested elsewhere within the business.

Efficient systems reduce operating costs and help minimize environmental impacts by reducing greenhouse gas emissions while improving indoor air quality.

Improved indoor air quality is another benefit. Efficient HVAC units are better at controlling humidity and filtering out pollutants, leading to a healthier working environment for everyone in the building.

Investing in an efficient industrial HVAC system isn’t just good for business but benefits employees and our planet.

Regular check-ups, investing in system upgrades, or improving insulation are just a few ways to boost your HVAC performance. These steps enhance comfort and contribute positively towards reducing energy costs and carbon emissions while improving indoor air quality.

Maintenance and Servicing of Industrial HVAC Systems

Industrial HVAC systems need regular care to perform at their best, like any complex machinery. This not only means troubleshooting problems when they arise but also preventive maintenance.

The Necessity of Regular Maintenance

A well-maintained industrial HVAC system runs more efficiently, meaning significant energy savings over time. But it’s not just about saving money; routine servicing is critical for safety, too.

If your system isn’t adequately maintained, harmful gases could be leaked into the work environment. Therefore, proactive upkeep goes a long way in ensuring the health and comfort of everyone on site.

Servicing: More Than Just Fixes

Many people think that service calls are just for when something breaks down – far from it. Routine servicing helps identify potential issues before they become costly repairs or cause unexpected downtime.

An experienced technician can spot wear and tear on parts during a routine inspection and replace them before failure occurs. According to Energy.gov, cleaning coils alone can increase efficiency by 15%.

Creating an Effective Maintenance Plan

To start maintaining your industrial HVAC system effectively, you should first understand what type of equipment you have because different types require varying levels of attention.

You’ll then want to establish a schedule based on this understanding. A good rule of thumb is to have preventative checks done semi-annually – once in spring before the cooling season starts and once in fall ahead of the heating period. As noted by HPAC, neglecting this routine can lead to a 10% – 25% increase in energy costs.

Hiring Professionals for Servicing

While you can do some maintenance tasks on your own, like changing filters or cleaning the system exterior, many aspects of HVAC servicing need professional help. A certified technician has the necessary training and tools to carry out complex jobs safely and efficiently.

Moreover, they’ll benefit from this.

Regular care of industrial HVAC systems is crucial for efficiency, safety, and cost-savings. This isn’t just about fixing problems but proactive maintenance to prevent issues from escalating. An effective plan involves understanding your equipment type, setting a servicing schedule, and hiring professionals when needed.

Cost Factors in Industrial HVAC Systems

Understanding the cost factors involved is essential when planning an industrial HVAC system. The initial investment isn’t your only concern; running costs and potential savings also play a significant role.

The Initial Investment

Regarding large commercial spaces, the initial cost of industrial HVAC systems can be pretty hefty. These costs include equipment purchase and installation fees. It’s crucial to note that quality doesn’t always come cheap; going for less expensive units may lead to more expenses due to frequent breakdowns or higher energy consumption.

Running Costs

Beyond the initial setup, there are ongoing operational expenses. According to EIA data, energy use tops this list because heating, ventilation, and air conditioning systems are known to power consumers. Regular maintenance helps ensure optimal performance but also contributes towards running costs.

Potential Savings through Efficiency

An efficient system could offer substantial long-term savings despite a heftier price tag initially. Features like programmable thermostats and variable-speed drives can reduce energy usage significantly over time, per DOE guidelines. You might pay more initially for these features, but lower operating expenses mean a better return on investment (ROI).

Maintenance Costs

Scheduled servicing extends your system’s lifespan and keeps efficiency levels high, leading to cost-saving benefits. Energy Star’s maintenance guide offers valuable tips on how to keep these costs manageable.

Tax Credits and Incentives

To promote energy efficiency, various tax credits and incentives are available for businesses that invest in efficient HVAC systems, as shown by DSIRE USA. These can offset some of your initial investment and ongoing operational expenses.

It’s clear that while industrial HVAC systems may require a significant outlay at the outset, understanding the cost factors involved can help you make informed decisions and save money in the long run.

Plus, don’t forget about tax incentives. They can be a big help when investing in efficient HVAC systems. Making smart choices now could save you loads of money down the road.

Future Trends in Industrial HVAC Technology

Industrial HVAC technology is not standing still. It’s evolving rapidly, driven by the need for more efficient and sustainable solutions. Here are some trends shaping its future.

Smart Controls

The rise of smart controls is changing how we manage industrial HVAC systems. These tools use advanced algorithms to adjust temperature and airflow automatically, optimizing comfort while reducing energy consumption.

This shift towards automation means less manual monitoring, allowing facility managers to focus on other tasks. But it’s not just about convenience; smart controls can also identify issues before they become costly problems.

Sustainable Technologies

The topic of sustainability is gaining traction in the industrial HVAC sector, and its implementation is being seen as a key factor for success. Innovations like geothermal heating or cooling systems tap into renewable resources to maintain indoor temperatures with minimal environmental impact.

Geothermal systems, for example, leverage stable underground temperatures to heat or cool buildings efficiently throughout the year—no matter what weather conditions may be above ground.

Air Purification Systems

In our health-conscious world, where clean air matters more than ever, air purification technologies also make waves in industrial HVAC circles. ‘Sick building syndrome’, caused by poor indoor air quality (IAQ), significantly impacts productivity levels—a problem improved IAQ aims to fix.

Maintenance Goes Digital

With the rise of Industry 4.0, maintenance for industrial HVAC systems is also taking a digital turn. Predictive maintenance uses real-time data and machine learning to predict potential system failures before they occur.

This approach helps prevent unexpected downtime, extends equipment life, and can lead to significant cost savings in the long run. It’s safe to say that these trends point towards an exciting future for industrial HVAC technology.

Industrial HVAC technology is racing forward, powered by the push for efficiency and sustainability. Smart controls are automating temperature management and spotting problems early. Sustainability drives innovations like geothermal systems that use renewable resources to regulate temperatures. Air purification technologies aim to fix poor indoor air quality, while digital maintenance predicts system failures before they happen, saving time and money.

FAQs in Relation to Industrial HVAC

What is considered industrial HVAC?

Industrial HVAC systems handle heating, ventilation, and air conditioning for large-scale facilities like factories, warehouses, or significant commercial buildings.

What is the difference between residential, commercial, and industrial HVAC?

Residential units serve homes. Commercial ones cover businesses. Industrial types are for vast spaces like plants or warehouses with more power and complexity.

What is commercial and industrial HVAC?

A blend of heating, cooling, and ventilating equipment that manages temperature and air quality in business places (commercial) or massive infrastructures (industrial).

What are the four main types of HVAC systems?

The four fundamental types are split Systems, Duct-Free Systems, Packaged Heating and air Units, and Heat Pumps, each with unique strengths based on use-case requirements.

Conclusion

So, what is industrial HVAC? It’s more than just temperature control. It’s a complex system that breathes life into large spaces.

These beasts aren’t all the same, though. Different types serve different purposes, and knowing which to use can make or break your comfort levels.

Maintenance matters, too. Regular servicing ensures optimal performance while energy efficiency keeps costs down and our planet healthier.

Speaking of cost, don’t let initial investments scare you away! Consider long-term savings through smart controls and sustainable technologies – the future trends worth watching!

To sum up, understanding industrial HVAC systems is no small feat, but it certainly pays off in ensuring comfort at work for everyone involved!

Hailing from the picturesque town of Lake Charles, Louisiana, Jim Blanchard stands as an exemplar in commercial HVAC installation and services. As President of Calcasieu Mechanical, he has leveraged his deep industry knowledge and innovative strategies to establish the company as a leading regional service provider. Under Jim’s leadership, Calcasieu Mechanical has expanded its portfolio of high-quality services and earned the trust and respect of businesses throughout Louisiana. The company’s commitment to excellence, reflected in its endeavors, stems from Jim’s dedication to ensuring every project meets and exceeds client expectations.