Maximize Comfort: Your Guide to Commercial HVAC Solutions

February 8, 2024Guide to HVAC Chiller Repair and Maintenance

April 2, 2024Stepping into the world of industrial HVAC is like unlocking a complex puzzle that powers our workplaces and factories. This isn’t just about cooling or heating; it’s an intricate dance of engineering marvels designed to keep operations running smoothly, no matter what Mother Nature throws at us. Exploring the realm of industrial HVAC unveils its distinctiveness from the quiet systems in our residences, illuminates the diversity suited for various industrial applications, and highlights why ongoing upkeep is not merely advisable but critical to ensuring both operational effectiveness and extended durability.

Moreover, we’ll thoroughly explore ways to enhance energy savings while ensuring systems operate at peak performance, directly address frequent design obstacles with actionable advice, and assist in pinpointing the perfect setup that aligns with your site’s specific needs. Moreover, you’ll see these concepts come to life through real-world examples, providing a window into how diverse sectors have implemented them successfully.

And because we’re always looking forward—together we’ll explore emerging trends set to revolutionize industrial HVAC technology. Consider this your guide through the intricate maze of industrial temperature management.

Table of Contents:

- Understanding Industrial HVAC Systems

- Types of Industrial HVAC Systems

- Importance of Maintenance for Industrial HVAC

- Energy Efficiency in Industrial HVAC

- Challenges in Industrial HVAC Design and Operation

- Selecting the Right Industrial HVAC System

- Case Studies on Successful Industrial HVAC Installations

- Future Trends in Industrial HVAC Technology

- FAQs in Relation to Industrial Hvac

- Conclusion

Understanding Industrial HVAC Systems

When you step into a large factory or warehouse, the comfortable temperature isn’t by chance. It’s all thanks to industrial HVAC systems, which are the unsung heroes in these vast spaces. Unlike their residential cousins, these systems have to tackle unique challenges like extreme temperatures and air quality control for larger areas.

Components of Industrial HVAC Systems

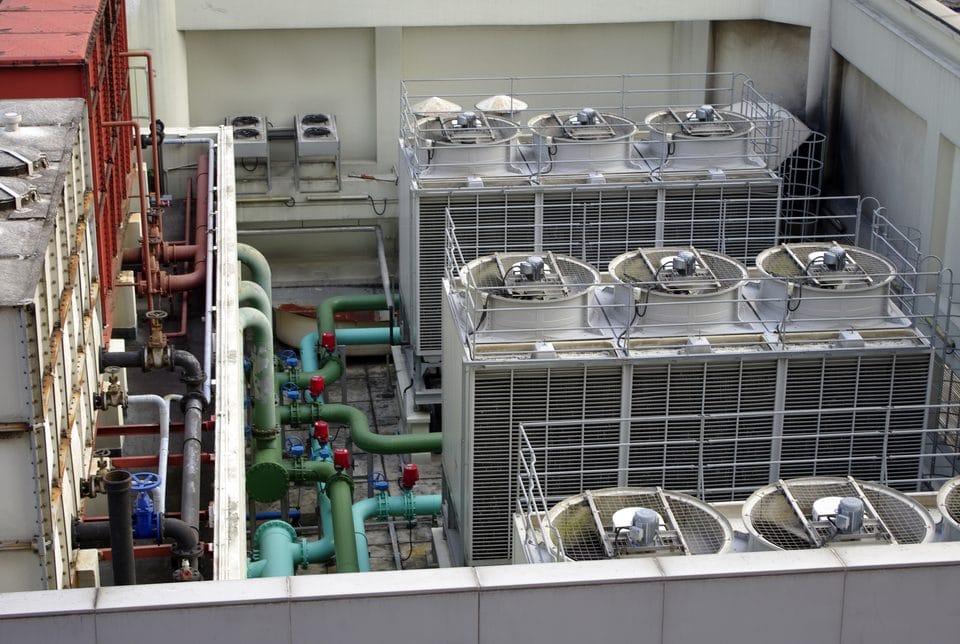

The backbone of any industrial HVAC system includes chillers, boilers, cooling towers, and extensive ductwork. Chillers help in cooling down the environment; they’re essentially giant refrigerators for your workspace. Boilers do the opposite by providing heat through steam or hot water circulation. Cooling towers aid in removing excess heat from the system to keep everything running smoothly.

Ductwork might not sound exciting but think of it as the circulatory system that delivers fresh air exactly where it’s needed most. In unison, these elements diligently operate out of sight to ensure the perfect environment for both equipment and workers.

Difference Between Residential and Industrial Systems

The scale is what sets industrial systems apart from residential ones; we’re talking about managing climate control over acres instead of square feet. But size isn’t the only difference—industrial setups need precise humidity controls and robust filtration methods to ensure air quality standards meet strict regulations. EPA regulations underscore the paramount importance of indoor air quality for fostering a secure work atmosphere.

Maintenance also shifts up several gears when you go industrial due to complexity. The stakes are high—if an essential component fails during peak operation times, it can lead to significant downtime costs. So while Aunt Edna’s window unit might need a filter change once every blue moon, an industrial chiller requires regular check-ups by professionals who know precisely what makes them tick—or more importantly, what could make them stop ticking.

Types of Industrial HVAC Systems

Industrial HVAC systems are the unsung heroes in large facilities, keeping everything from machinery to employees working at their best. Unlike their residential cousins, these systems need to cover more ground and handle intense conditions.

All-Air Systems

All-air systems offer a straightforward approach by using air as both the cooling and heating medium. They’re like that reliable truck in your fleet; not always flashy but get the job done efficiently. These systems can be further broken down into single-zone, multi-zone, and variable air volume (VAV) systems. Each type has its niche, with single-zone being ideal for spaces with uniform climate needs while VAVs shine in areas where temperature requirements fluctuate.

The simplicity of all-air setups makes them easier to maintain than other types. But remember, they might struggle in extremely humid or polluted environments because they rely solely on air without any direct cooling or heating sources.

Air-Water Systems

Mixing things up a bit are the air-water HVAC setups which use both mediums for temperature control—think of it as having your cake and eating it too. These hybrids provide better humidity control compared to all-air solutions and can be tailored for specific zones within an industrial setting without breaking a sweat (or causing one).

The versatility comes at a cost though: complexity increases which means you’ll need skilled technicians who know their way around these dual-threat units.

Radiant Panels

Last but not least are radiant panel systems that bring heat directly from surfaces—floors or ceilings—to people and objects in the room without warming the air first. It’s akin to feeling sunbeams on your face during winter; gentle yet effective warmth exactly where needed.

This method is energy-efficient since there’s no energy lost through ductwork leakage—a common issue with forced-air methods—but installation costs can make some facility managers pause before diving headfirst into this option.

Importance of Maintenance for Industrial HVAC

Maintenance in the industrial HVAC world isn’t just a good idea; it’s your system’s lifeline. Think about it like this: You wouldn’t drive your car without regular oil changes, right? The same logic applies here but on a much larger scale.

Preventing Costly Breakdowns

The number one reason to stay on top of your industrial HVAC maintenance is simple – preventing those oh-no moments when everything grinds to a halt because something broke down. Frequent inspections ensure minor glitches are identified early on, forestalling major setbacks and thus conserving both your resources and hours. It’s not just about fixing things that are broken; it’s about keeping them from breaking in the first place.

A study highlighted by the U.S. Department of Energy shows that preventive maintenance leads to savings of up to 30% over reactive maintenance strategies. That’s huge, especially considering the size and scope of industrial systems.

Boosting Efficiency and Reducing Costs

By ensuring routine upkeep, we not only dodge malfunctions but also optimize our system’s performance to its fullest potential. Dirt buildup reduces efficiency — every extra pound of dirt or dust in your system can significantly increase energy consumption.

This means higher utility bills for less effective cooling or heating. A clean system is an efficient one which translates directly into cost savings for you and better performance overall.

An example worth noting comes from studies conducted by organizations such as ASHRAE (American Society of Heating, Refrigerating and Air-Conditioning Engineers), showing how regular filter replacements alone can improve efficiency by 5% to 15%. Imagine what more comprehensive care could do.

Energy Efficiency in Industrial HVAC

Boosting energy efficiency in industrial HVAC systems isn’t just about saving on utility bills. Adopting this savvy approach not only cuts down on expenses but also diminishes our ecological impact, benefiting both commerce and nature. Let’s explore how modern technologies and practices are reshaping this landscape.

Smart Thermostats and Automation Systems

At the core of a proficient system is its knack for evolving. Smart thermostats go beyond basic temperature adjustments; they learn from your usage patterns to optimize heating and cooling schedules without human intervention. This means your system works only as hard as it needs to, slashing energy use significantly.

Besides, automation systems integrate with various building management systems (BMS), allowing for centralized control of not just HVAC but lighting, security, and more. The result? You get an operation that’s smooth as silk, slashing energy costs like nobody’s business.

VRF Systems: Adaptable Solutions for Diverse Needs

Variable Refrigerant Flow (VRF) technology is another game-changer in the realm of industrial HVAC efficiency. By finely tuning the refrigerant’s flow to meet immediate needs, these mechanisms maintain peak efficiency round-the-clock.

The beauty of VRF lies in its flexibility—capable of both heating and cooling different parts of a facility simultaneously if needed. Hence, buildings with diverse space needs particularly reap the rewards of VRF technology’s adaptability.

Maintenance: The Unsung Hero of Efficiency

No matter how advanced an HVAC system might be, neglecting regular maintenance can turn any potential gains into losses quickly. Clogged filters and faulty parts exert undue pressure on the whole setup, escalating energy usage. Therefore scheduling regular check-ups by professionals who understand these complex machines inside out ensures everything runs smoothly, reducing breakdown risks while keeping those energy costs down.

Challenges in Industrial HVAC Design and Operation

Designing and operating an industrial HVAC system is like trying to solve a Rubik’s Cube blindfolded. You know it’s possible, but boy, does it throw some curveballs your way.

Complexity of Customization

The one-size-fits-all approach doesn’t fly here. Each manufacturing plant is a world of its own, defined by its dimensions, purpose, and geographical position. This means every HVAC system must be tailor-made to fit these requirements perfectly. Imagine custom-fitting a suit for an octopus; that’s the level of customization we’re talking about.

To navigate this maze, professionals often turn to ASHRAE guidelines, which serve as the North Star for designing systems that meet both performance standards and energy efficiency goals.

Balancing Energy Efficiency with Performance

In the world of industrial HVACs, being eco-friendly isn’t just nice—it’s necessary. But striking the perfect balance between green practices and keeping a factory cool or warm is akin to walking a tightrope while juggling fire torches.

Luckily, innovations such as variable frequency drives (VFDs) have come into play—think of them as dimmer switches for your motors—allowing systems to use only as much power as needed at any given time.

Maintenance: The Never-Ending Story

A well-oiled machine keeps running smoothly until it doesn’t—and then you remember maintenance was due last month. Regular upkeep is critical in avoiding unexpected breakdowns which can halt production faster than you can say “HVAC”. It requires vigilance because let’s face it; out-of-sight usually becomes out-of-mind until something goes wrong.

Implementing routine check-ups through service agreements can save industries from experiencing their very own horror movie scenario where everything that could go wrong does indeed go awry at peak times.

Selecting the Right Industrial HVAC System

Finding the perfect industrial HVAC system is a bit like matchmaking for your facility. You need a system that complements your space’s unique needs, ensuring comfort without breaking the bank.

Understanding Your Facility’s Needs

The first step in choosing an HVAC system is getting to know your facility inside and out. Ponder the dimensions, structure, and functional demands of your space. A sprawling warehouse has different needs than a compact manufacturing plant.

Ponder over the potential for expansion down the road as well. An adaptable system can grow with you, saving money down the line.

Evaluating Energy Efficiency

Nowadays, the necessity of energy efficiency transcends mere convenience; it has become a critical component. Adopting streamlined mechanisms not only trims expenses but also favors environmental sustainability. Look into systems with high SEER (Seasonal Energy Efficiency Ratio) ratings or those certified by ENERGY STAR for their efficiency gains.

Beyond initial certifications, consider long-term sustainability practices within your operations that could enhance these efficiencies further.

Maintenance Matters

A great HVAC system won’t stay great without proper upkeep. Before making a choice, ask about maintenance plans and ease of serviceability.

Ongoing maintenance not only ensures optimal performance but also extends the lifespan of your investment—a win-win scenario if there ever was one.

Tech-Savvy Solutions

Modern problems require modern solutions—this holds for industrial HVAC systems too. Innovations like smart thermostats let you control settings from anywhere at any time offering unparalleled convenience and efficiency boosts.

Digital integration can streamline operations and provide insights into usage patterns, helping make informed decisions on heating and cooling strategies moving forward.

Case Studies on Successful Industrial HVAC Installations

When it comes to industrial HVAC, the proof is in the pudding—or rather, in the real-world applications that show us what works and what doesn’t. We’ve seen everything from massive chillers humming away in food processing plants to sleek, energy-efficient systems keeping tech warehouses cool.

Understanding Industrial HVAC Systems

The backbone of any large facility’s operation often rests on its heating, ventilation, and air conditioning (HVAC) system. But not all systems are created equal. Some are built to withstand the grueling heat of a steel mill; others are designed with precision for clean rooms where even a slight temperature fluctuation could ruin product batches worth millions.

Exploring real-world examples unveils the nuances of mastering these intricate systems, illuminating the path to their successful domestication. For example, consider a case study from an automotive assembly plant that needed to overhaul its outdated HVAC system without halting production—a task akin to changing tires on a moving car.

Types of Industrial HVAC Systems

Delving into the myriad configurations of industrial environments, we stumble upon a diverse palette of systems crafted to meet distinct requirements. There’s no one-size-fits-all here; each facility has unique challenges whether it’s managing humidity levels in textile mills or ensuring sterile air quality in pharmaceutical manufacturing.

Delving into the comparison between age-old chiller systems and contemporary VRF tech sheds light on how innovation has paved the way for more adaptable, cost-effective solutions in maintaining prime work environments.

Maintenance: The Unsung Hero

Last but certainly not least is maintenance—the unsung hero keeping these giants running smoothly day after day. Regular upkeep isn’t just about preventing breakdowns; it’s crucial for extending equipment life span and maximizing efficiency over time.

One standout example involved implementing predictive maintenance strategies at a data center using advanced analytics tools which resulted in significantly reduced downtime and operational expenses—a clear testament that when done right, maintenance can transform potential headaches into powerful advantages.

Future Trends in Industrial HVAC Technology

The industrial HVAC landscape is buzzing with innovations that promise to redefine comfort, efficiency, and sustainability. Marching into tomorrow, these advancements in technology are no longer mere murmurs of transformation but vibrant discussions on radically altering our perception of heating, ventilation, and air conditioning across the board.

Smart Systems and IoT Integration

In this age, the influence of intelligent tech has profoundly permeated the realm of industrial heating, ventilation, and air conditioning systems. The integration of the Internet of Things (IoT) allows for unprecedented control over climate systems from anywhere in the world. Imagine adjusting settings or troubleshooting issues without having to be physically present at the facility. Harnessing this kind of connectedness guarantees peak operation and slashes power use in a big way.

Moreover, predictive maintenance powered by AI algorithms can anticipate system failures before they happen. By analyzing data trends over time, these intelligent systems can notify operators when components need servicing or replacement—effectively preventing downtime and extending equipment lifespan.

Rise of Eco-friendly Solutions

Sustainability is no longer an option but a necessity in today’s industrial operations. Newer HVAC technologies are leaning towards greener solutions that minimize environmental impact without compromising performance. For instance, advanced refrigerants with lower global warming potential (GWP) are replacing traditional ones known for their harmful effects on our planet’s ozone layer.

In addition to eco-friendly refrigerants, renewable energy sources like solar power are being integrated into HVAC systems to further reduce carbon footprints.

By embracing this transition, companies not only align with worldwide sustainability objectives but also witness substantial financial benefits via decreased energy expenses as time progresses.

FAQs in Relation to Industrial HVAC

How does an industrial HVAC system work?

An industrial HVAC system controls a building’s climate by heating, cooling, and ventilating large spaces efficiently.

What is the difference between industrial and commercial HVAC?

Industrial systems handle larger areas with more complex needs than commercial ones, which serve smaller businesses or venues.

What is industrial air conditioning?

It’s a heavy-duty cooling setup designed to maintain optimal temperature in big factories or warehouses.

What size unit for industrial HVAC?

The right size depends on your space’s square footage and specific requirements. Always consult with an expert first.

Conclusion

Deciphering the intricacies of industrial HVAC systems equates to assembling a multifaceted jigsaw. You’ve learned it’s more than just heating or cooling; it’s about ensuring operations run smoothly.

Key takeaways? Keeping up with upkeep is not a choice—it’s crucial for keeping things running optimally and extending their life span. Energy-saving strategies don’t have to compromise performance, but rather, they enhance it.

Selecting the optimal system requires a deep comprehension of your facility’s distinct demands. And remember, staying ahead means keeping an eye on future trends in HVAC technology.

So dive in, use what you’ve learned here to make informed decisions, and let these insights guide you through mastering your industrial climate control challenges.

Hailing from the picturesque town of Lake Charles, Louisiana, Jim Blanchard stands as an exemplar in commercial HVAC installation and services. As President of Calcasieu Mechanical, he has leveraged his deep industry knowledge and innovative strategies to establish the company as a leading regional service provider. Under Jim’s leadership, Calcasieu Mechanical has expanded its portfolio of high-quality services and earned the trust and respect of businesses throughout Louisiana. The company’s commitment to excellence, reflected in its endeavors, stems from Jim’s dedication to ensuring every project meets and exceeds client expectations.